Drain Field

Septic Stack™ Systems (PDF)

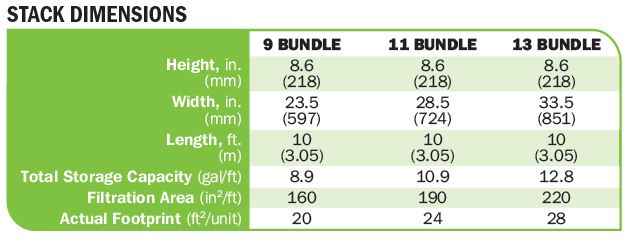

Available in configurations of 9, 11, and 13 pipes, Septic Stack units allow for exceptional soil contact without the use of gravel. The Septic Stack units function as a trickle filter, dispersing effluent into the voids in and around the specially-banded ADS pipe. This pipe is engineered with holes and slots, allowing it to collect and disperse the effluent as it passes over the corrugations in the pipe. ADS Septic Stack Systems are available for use in both residential and commercial applications. Contact your local Health Department or County

Sanitarian for information on which sizes meet your state & local requirements.

Applications:

Trench Configuration * Bed Configuration * Mound Configuration

* Low Pressure Piping * Pressure Distribution

Features & Benefits:

-

- Using 4” (100 mm) HDPE pipe provides excellent

abrasion and corrosion resistance

- Using 4” (100 mm) HDPE pipe provides excellent

-

- Light weight

-

- 10’ lengths create fast installation times and allow tremendous design flexibility

-

- Structural strength that will support H-10 load rating with 12” of settled cover

-

- 8.6” (218 mm) height provides low profile

-

- High storage volume

-

- Distribution pipe runs the entire length of system

Tanks

Infiltrator Septic Tanks (PDF)

The Infiltrator IM-1060 is a lightweight strong and durable septic tank. This watertight tank design is offered with Infiltrator’s line of custom-fit risers and heavy-duty lids. Infiltrator injection molded tanks provide a revolutionary improvement in plastic septic tank design, offering long-term exceptional strength and watertightness.

Features & Benefits

-

- Strong injection molded polypropylene construction

-

- Lightweight plastic construction and inboard lifting lugs allow for easy delivery and handling

-

- Integral heavy-duty green lids that interconnect with TW™ risers and pipe riser solutions

-

- Structurally reinforced access ports eliminate distortion during installation and pump-outs

-

- Reinforced structural ribbing and fiberglass bulkheads offer additional strength

-

- Can be installed with 6” to 48”

of cover

- Can be installed with 6” to 48”

-

- Can be pumped dry during

pump-outs

- Can be pumped dry during

-

- Suitable for use as a septic tank, pump tank, or rainwater (non-potable) tank

-

- No special water filling requirements

are necessary

- No special water filling requirements

-

- The tank may be back filled with suitable

native soil. See installation instructions

for guidance.

- The tank may be back filled with suitable

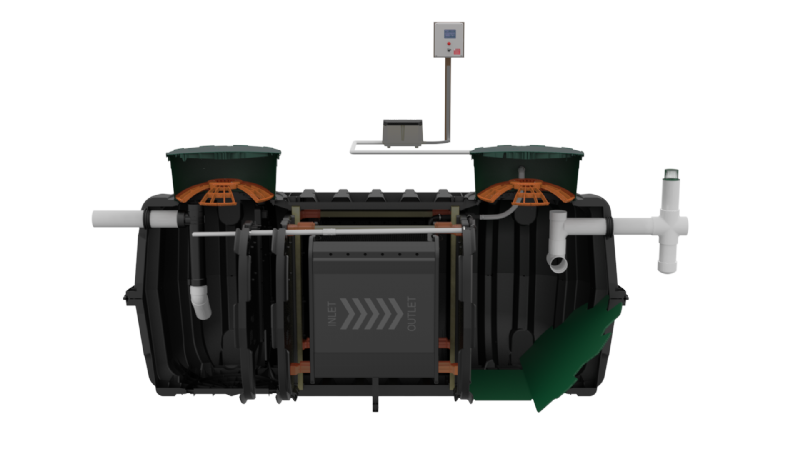

Infiltrator ECOPOD-Edge (PDF)

ECOPOD-Edge Advanced Wastewater Treatment Units are an innovative approach to onsite wastewater disposal where nitrogen reduction is required. The ECOPOD-Edge technology has been tested under NSF/ANSI 40 and 245 with an average nitrogen reduction of greater than 79% exceeding Class 1 requirements with an average effluent quality 9 mg/L CBOD, 8 mg/L TSS, and 11 mg/L Total Nitrogen.

ECOPOD-Edge Advanced Wastewater Treatment Units are an innovative approach to onsite wastewater disposal where nitrogen reduction is required. The ECOPOD-Edge technology has been tested under NSF/ANSI 40 and 245 with an average nitrogen reduction of greater than 79% exceeding Class 1 requirements with an average effluent quality 9 mg/L CBOD, 8 mg/L TSS, and 11 mg/L Total Nitrogen.

Specifications:

ECOPOD-Edge Advanced Wastewater Treatment Units are manufactured to specifications according to wastewater flow requirements available in the following models:

- Model E50-Edge 1060: 1 tank configuration

Features:

- ECOPOD-Edge uses a fixed film bioreactor with structured media to promote robust bacterial growth for effective wastewater treatment.

- It can be installed in a single CM-1060 Infiltrator tank for flexible site design.

- A single aerator is used to provide oxygen to the bacteria as well as to recirculate flow from the treatment chamber to the pre-treatment chamber.

- Engineered “Edge Zone” design creates anoxic subzones within the aerobic treatment chamber, supporting efficient nitrogen removal.

- ECOPOD-Edge units significantly reduce CBOD, TSS, and Total Nitrogen (TN) in the wastewater.

- Certified under NSF/ANSI 40 and 245 for high-level residential wastewater treatment performance.

Aerobic Treatment Tanks

Fuji Clean USA (PDF)

Since 1961 Fuji Clean has built and installed over two million treatment systems. The company is now the largest manufacturer in the world of onsite septic treatment systems thanks to superior product performance and long term attention to customer needs.

Since 1961 Fuji Clean has built and installed over two million treatment systems. The company is now the largest manufacturer in the world of onsite septic treatment systems thanks to superior product performance and long term attention to customer needs.

You want a system that is robust and uncomplicated.

Fancy “bells and whistles” and septic treatment do not mix well. Fuji Clean’s one- hole, one-tank, one-air system has no moving parts inside, requires no additives and is powered by one long-lasting linear diaphragm air blower with an expected runtime of 5+ years and that can be inexpensively rebuilt in 30 minutes.

ECOPOD-NX Infiltrator Tanks (PDF)

ECOPOD-NX directly contributes to a cleaner, safer environment using the bacteria nature provides. As a result of air being pumped into the system, the bacteria thrive and grow in much greater numbers than would occur naturally. This optimum population of bacteria accelerates the process of breaking down the sewage, making it safe for release into the environment.

Why Use ECOPOD-NX Advanced Wastewater Treatment?

-

- The moving bed bioreactor (MBBR) process provides a robust solution suitable for continuous or intermittent use

- Engineered solution with both NSF/ANSI 40 and NSF/ANSI 245 certifications

- Flexible and easy installations in Infiltrator tanks

- With no mechanical parts internal to the unit, the ECOPOD-NX is easy to maintain

- Designed specifically to minimize sludge production for lower long-term maintenance

- Low life cycle costs resulting from efficient design with minimal maintenance requirements

- Patented non-clogging air delivery system

- Support through a dedicated team of engineers who act like an extension of your own team

Pumps

Liberty Pumps (PDF)

1/2 hp

1-1/2″ Discharge

3/4″ Solids Handling

Features

• Liberty Pumps unique, one-piece

“Uni-Body” casting

• Quick-connect 10′ standard

power cord allows replacement of

cord in seconds without breaking

seals to motor (other lengths available)

• Permanently lubricated upper

and lower bearings

• Oil-filled, hermetically sealed motor

with thermal overload protection

• Stainless-steel removable bottom screen

• Stainless-steel rotor shaft

• Stainless-steel fasteners

Quick4 Equalizer 36 Chamber

Information Sheet (PDF)

The Quick4® Equalizer 36 Chamber fits in a 24” wide trench and works for both curved and straight systems, with the Contour Swivel Connection™ allowing 15° turns for added flexibility. The four-foot chamber is easy to handle, features a quick-install latching mechanism, and compact nesting for more trench length. Supporting wheel loads up to 16,000 lbs/axle with 12” of cover, it’s IAPMO certified. The MultiPort™ endcap offers multiple piping options, tear-out seals for a tight pipe fit, and six inlets/outlets for versatility, fitting on either end of the chamber.

The Quick4® Equalizer 36 Chamber fits in a 24” wide trench and works for both curved and straight systems, with the Contour Swivel Connection™ allowing 15° turns for added flexibility. The four-foot chamber is easy to handle, features a quick-install latching mechanism, and compact nesting for more trench length. Supporting wheel loads up to 16,000 lbs/axle with 12” of cover, it’s IAPMO certified. The MultiPort™ endcap offers multiple piping options, tear-out seals for a tight pipe fit, and six inlets/outlets for versatility, fitting on either end of the chamber.

-

- Advanced contouring connections swivel up to 15°, right or left

- Latching mechanism allows for quick installation

- Compact nesting provides more trench length in an equivalent stack height

- Four-foot chambers are easy to handle and install

- The Quick4 Equalizer 36 Chamber supports wheel loads of 16,000 lbs/axle with only 12” of cover

- Certified by the International Association of Plumbing and Mechanical Officials (IAPMO) MultiPort Endcap Benefits:

- Tear-out seals on inlet ports provide a tight fit to the pipe

- Six molded-in inlets/outlets allow for maximum piping flexibility

- Fits on either end of the Quick4 Equalizer 36 Chamber